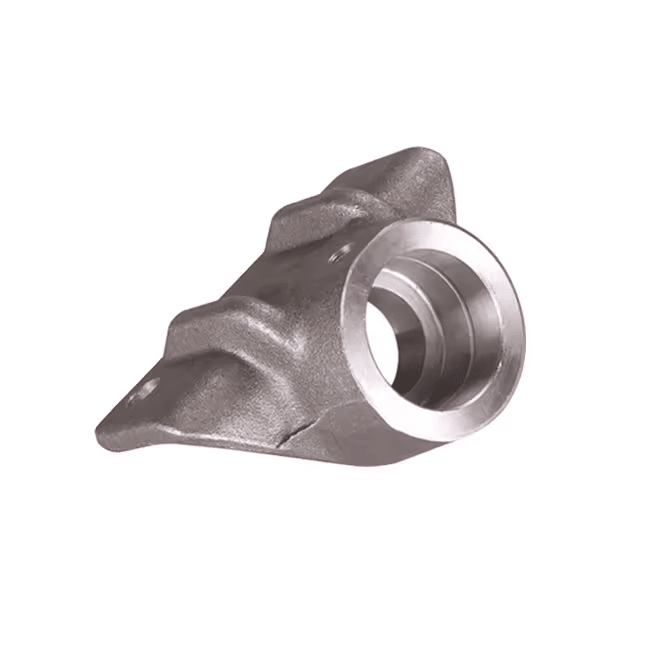

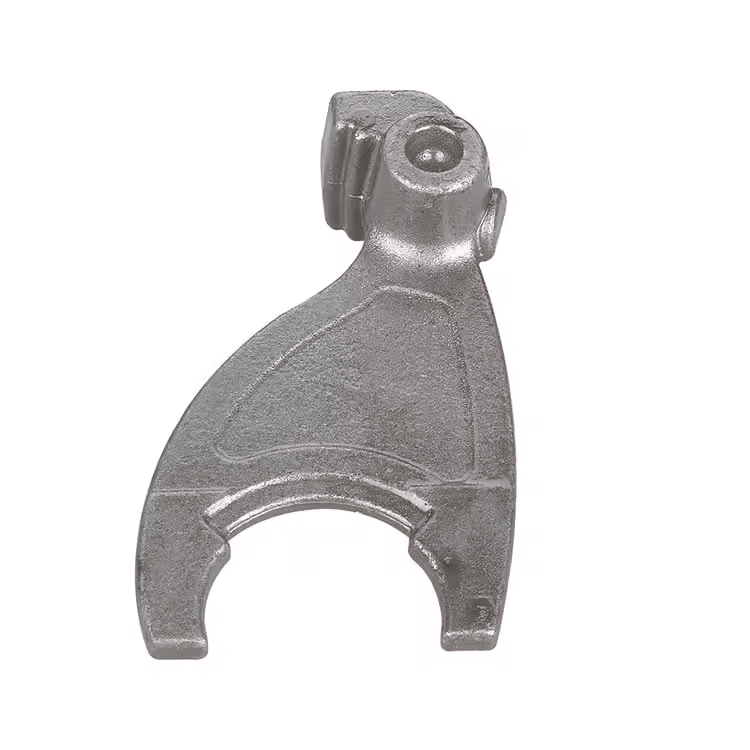

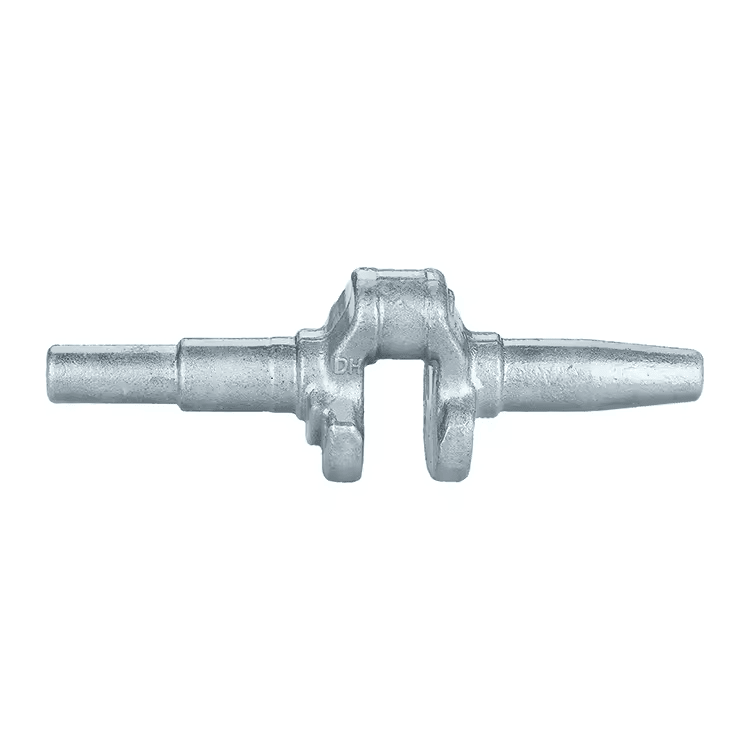

Cast Iron CI Casting Service Custom made special-shaped forging parts CNC machining forged spare parts Forging Part

- Overview

- Related Products

Overview

|

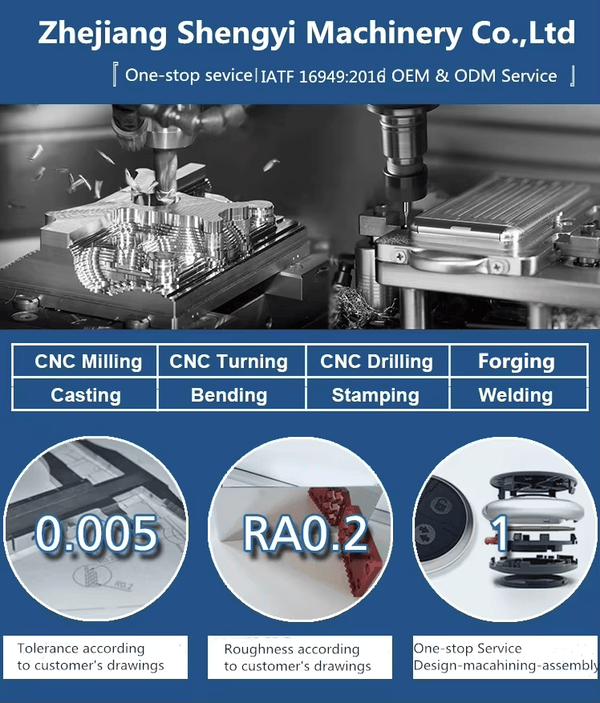

OEM Service

|

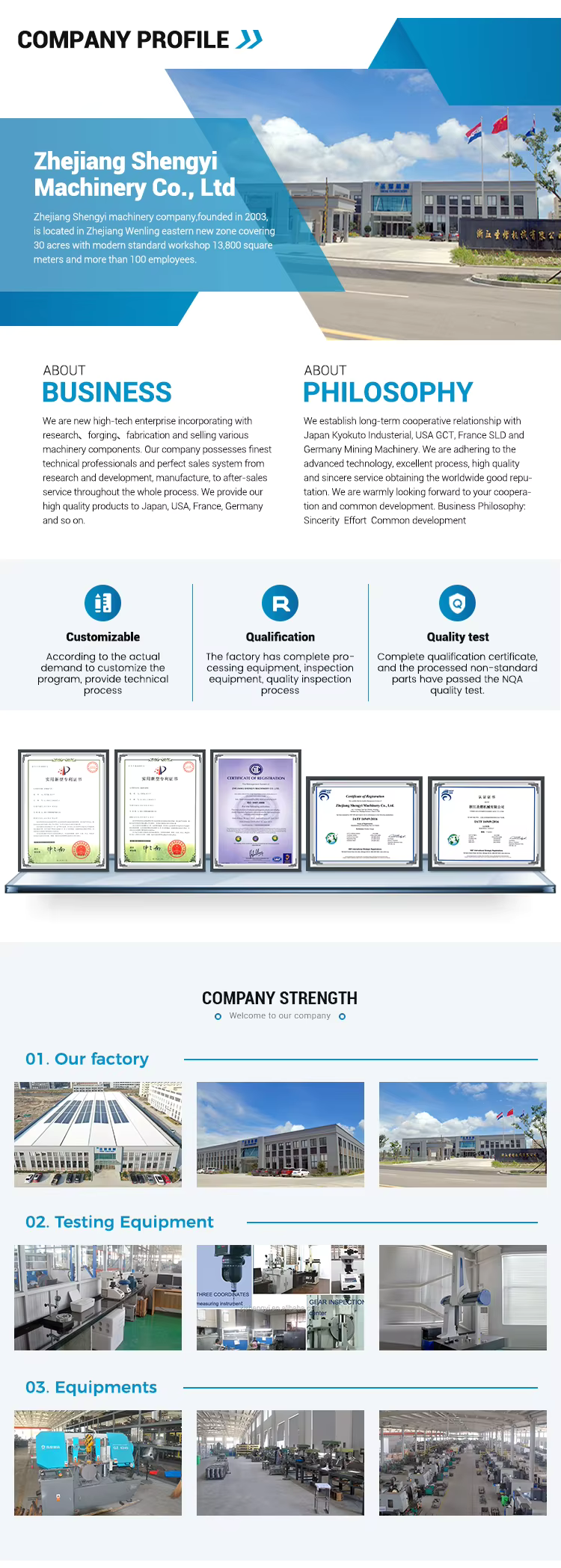

Zhejiang Shengyi Machinery Co.,Ltd

|

|

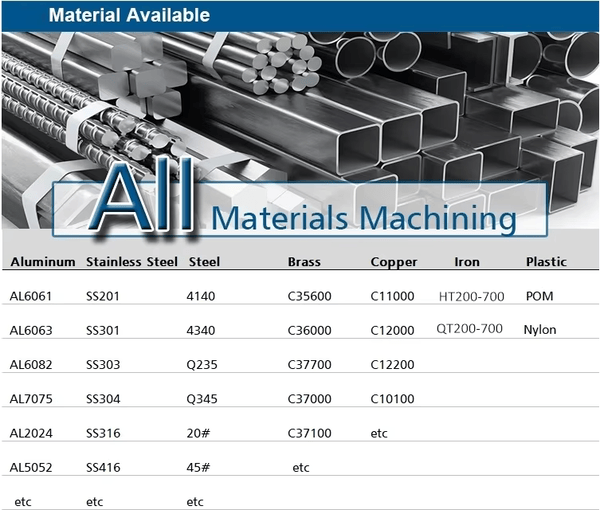

Available Material:

|

Brass,Copper,Carbon Steel,Stainless Steel,Steel Alloy,Aluminum Alloy,etc.

|

|

Heat Treatment:

|

Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc.

|

|

Tolerance:

|

As per drawing.(+/-0.05mm,+/-0.01mm)

|

|

Surface Treatment:

|

Zinc-Plated,Nickel-Plated,Chrome-Plated,Anodize,Phosphating,Chemical Blackening,Salt Bath Nitriding,etc.

|

|

Lead Time:

|

20-45Days Depends On Quantities and complexity

|

|

Application:

|

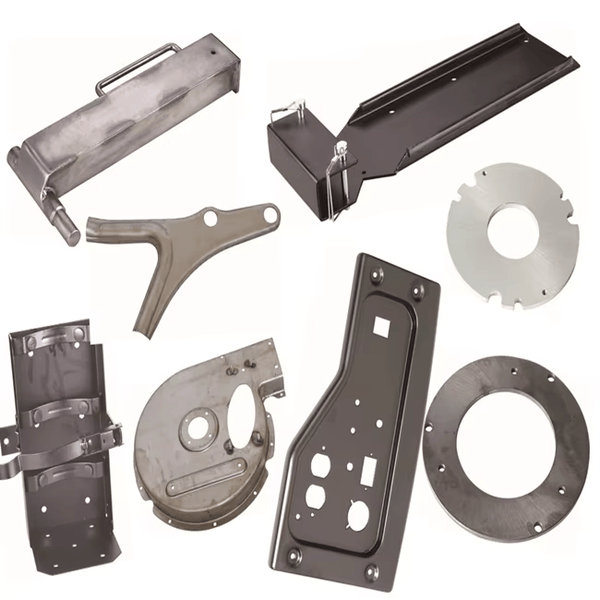

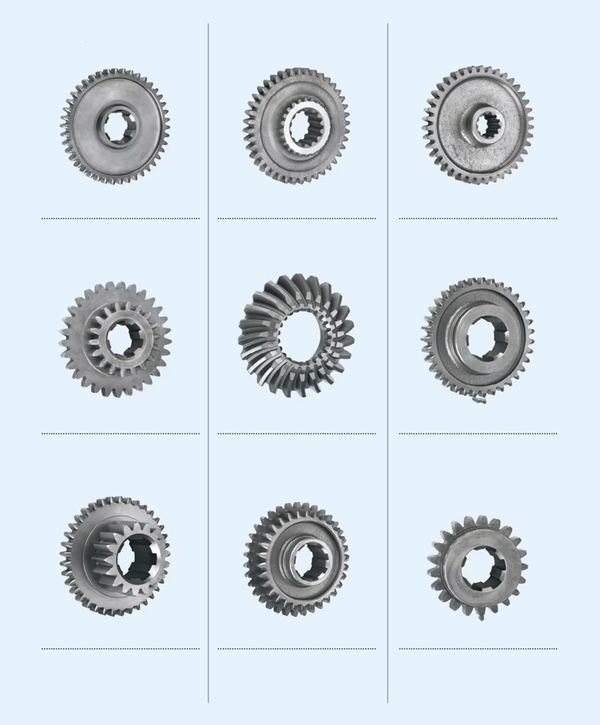

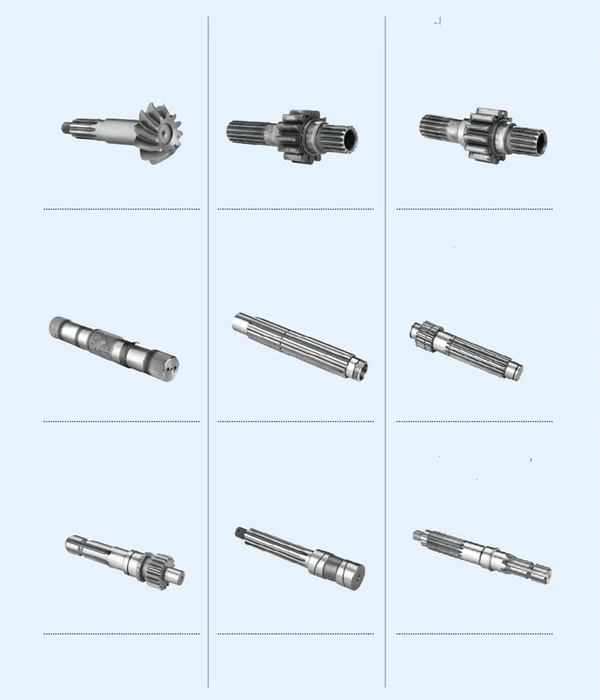

Forklift,Crane,Train,Truck,Lawnmower,Rail Road Euipment,medical device, industrial machine, automobile, electric appliance,Automation machine,other industries,etc,

|

|

Payment Term:

|

L/C at sight

T/T 30% deposit and balanced 70% to pay before shipment.

|

|

Port Of Loading:

|

Shanghai or Ningbo,etc.

|

|

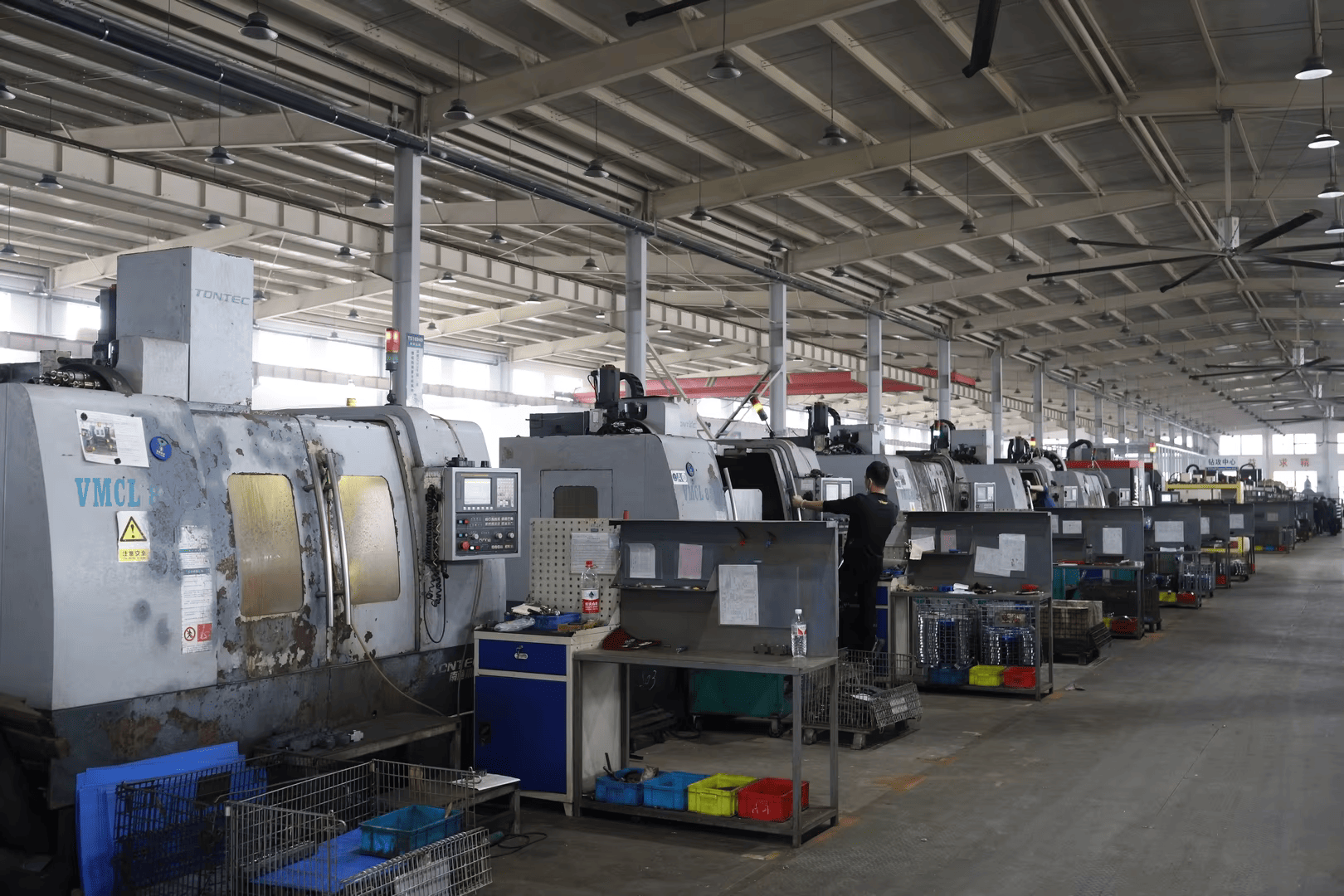

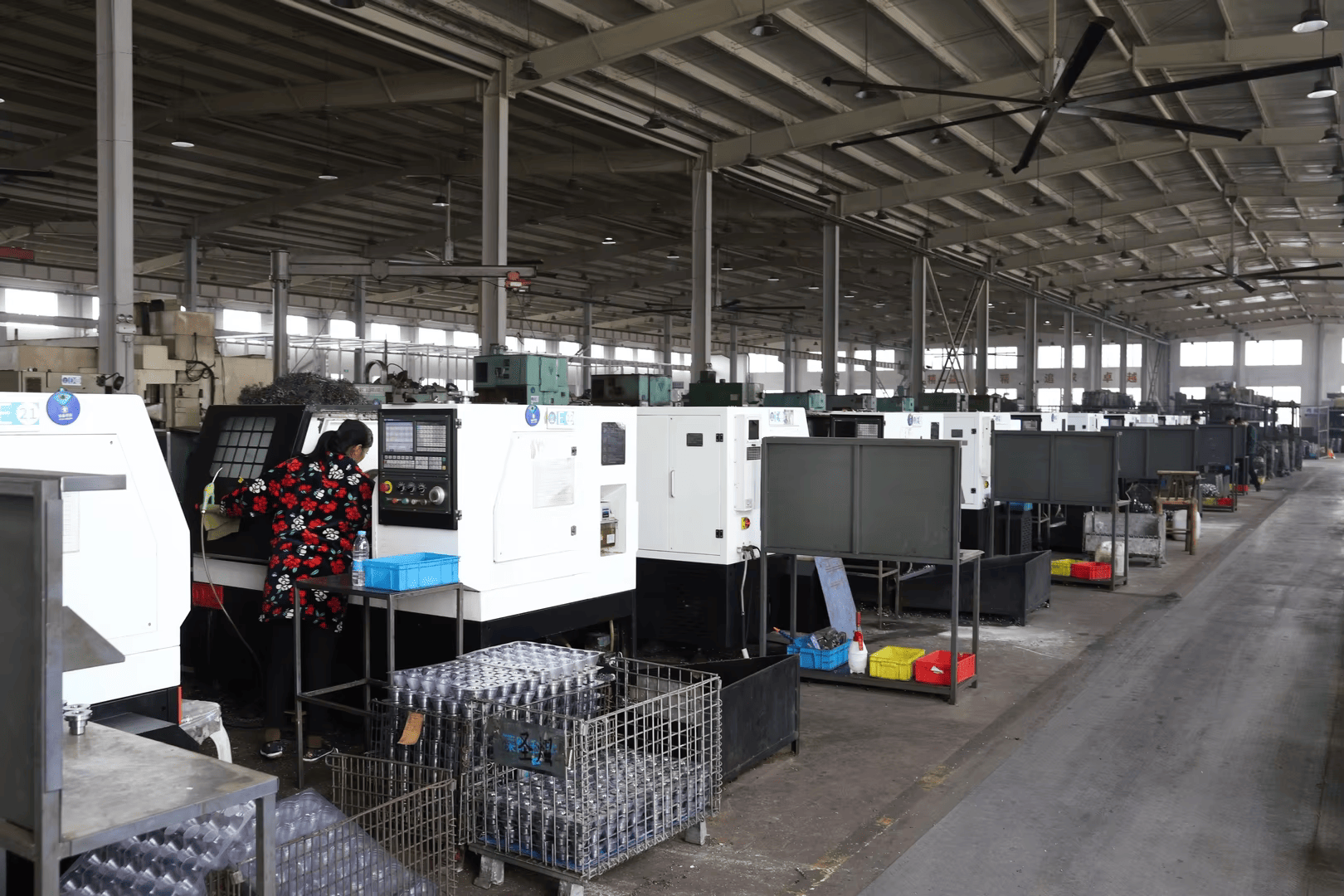

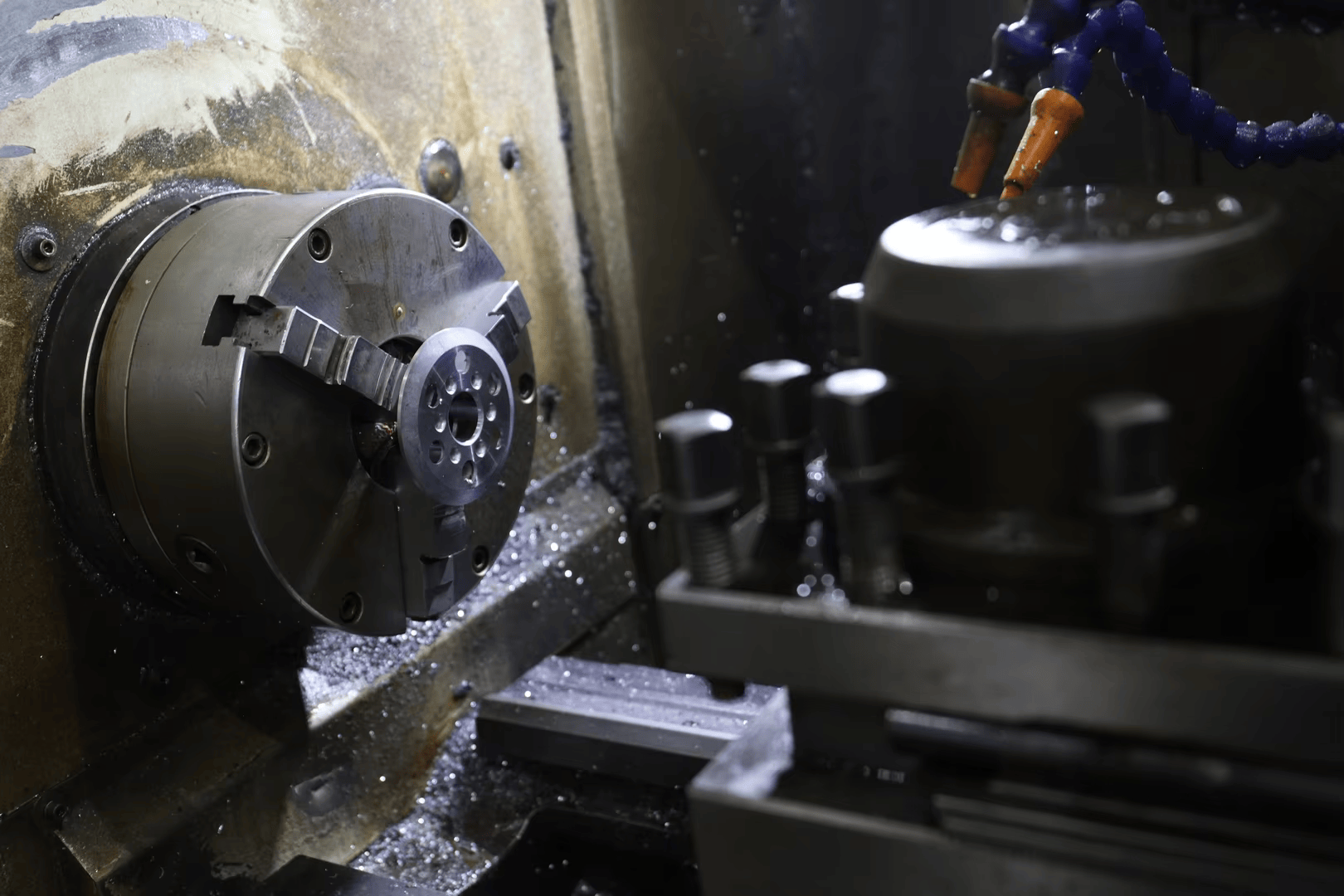

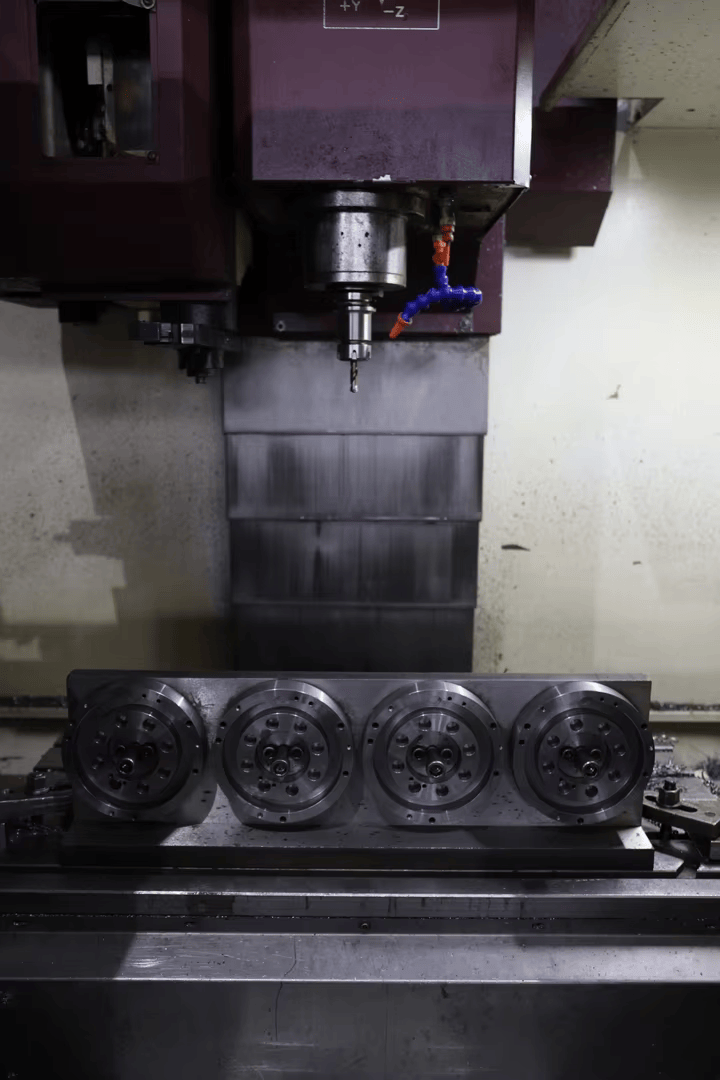

Production Equipment:

|

CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,Sawing Machine,Welding Machine,Hydraulic Press Machine,Drilling and Tapping Machine,Gear Shaping Machine,etc.

|

|

Inspection Equipment:

|

Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Ultrasonic Flaw Detector,Surface Roughness Measuring Instrument,Leeb Hardness Tester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc.

|

|

QC:

|

1.Incoming material will be checked before production.

2.Strict processing quality control.

3.100% inspection before shipment.

4.We are responsible for product quality to the end user.

|

|

Package:

|

Method 1:Carton box or corrugated carton

Method 2:Wooden case or wooden crate Method 3: Iron basket or plastic basket Method 4: Pallet |

|

After-sales Service:

|

We will follow up goods for customers and help to solve problems after sales.

|

|

We are a OEM factory to supply machinery parts according to the drawings oe samples.

Small order or sample order is acceptable.

|

|

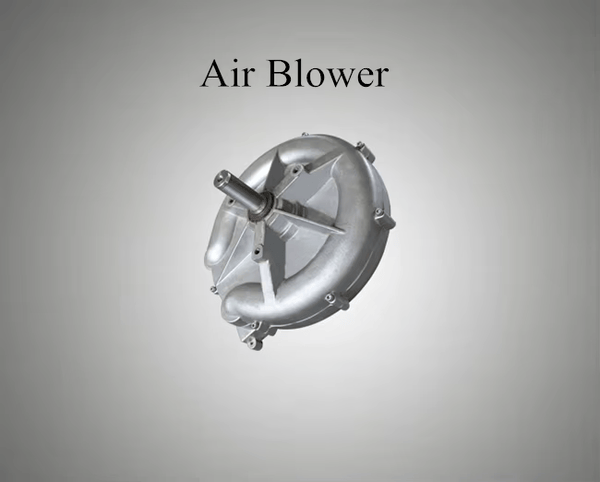

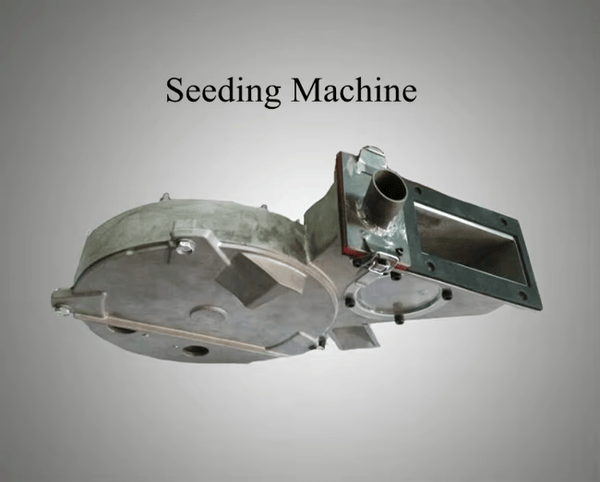

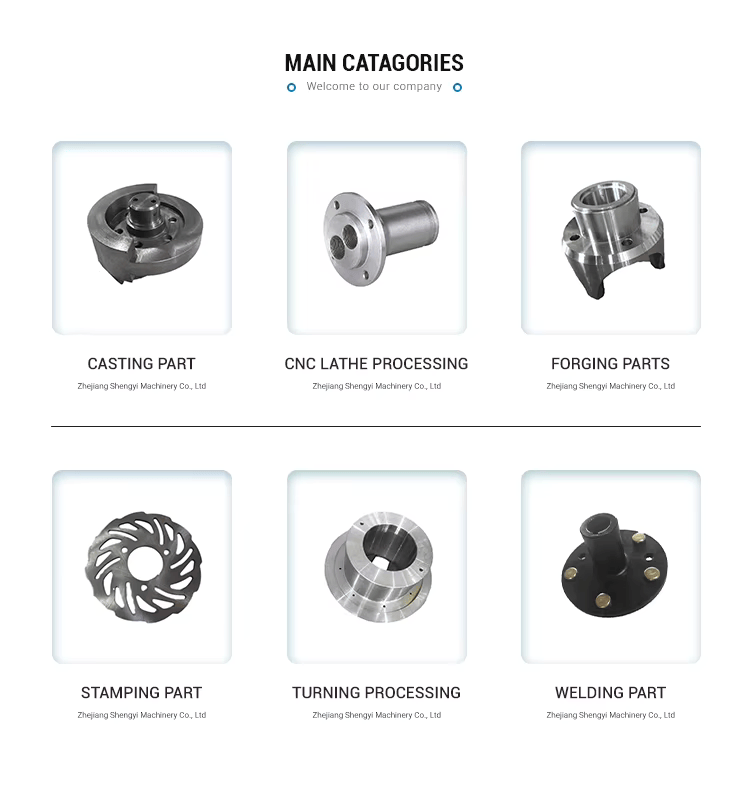

Products Display

Brake Disc

Gear

Gear Shaft

Processing

ASSEMBLY 1

ASSEMBLY 2

ASSEMBLY 3

ASSEMBLY 4

ASSEMBLY 5

ASSEMBLY 6